Vertigo

Non-contact geometric control

Vertigo is a system for the sampling verification of laboratory containers that can be directly installed on production lines (cold-end) and in the hot zone (hot-end) that verifies:

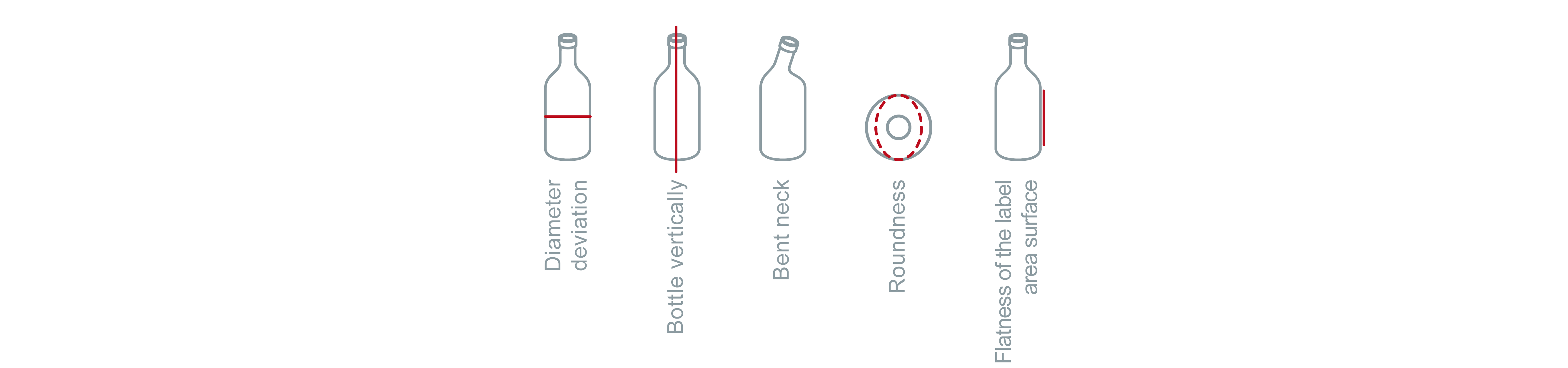

diameter measurement and calibration

deviation of container verticality

deviation of crooked neck

ovalization of container

flatness of the label area

The container under verification is manually placed by the operator on the designated rotating platform, and the system executes all checks (non-contact) in 10 seconds, sending the data directly to control software or company databases, effectively eliminating errors in mechanical positioning of probes, data entry errors, and ensuring repeatability of measurements over time.

Vertigo allows traditional SPC (Statistical Process Control) dimensional control activities to be replaced with an automatic and error-free tool in a faster and safer manner.

Highlighted Features

Fast manual recipe creation (2 minutes)

Direct receipt of recipes from the remote Vertech system

Reduction of measurement times (10 seconds for all measurements)

Data generation for Industry 4.0